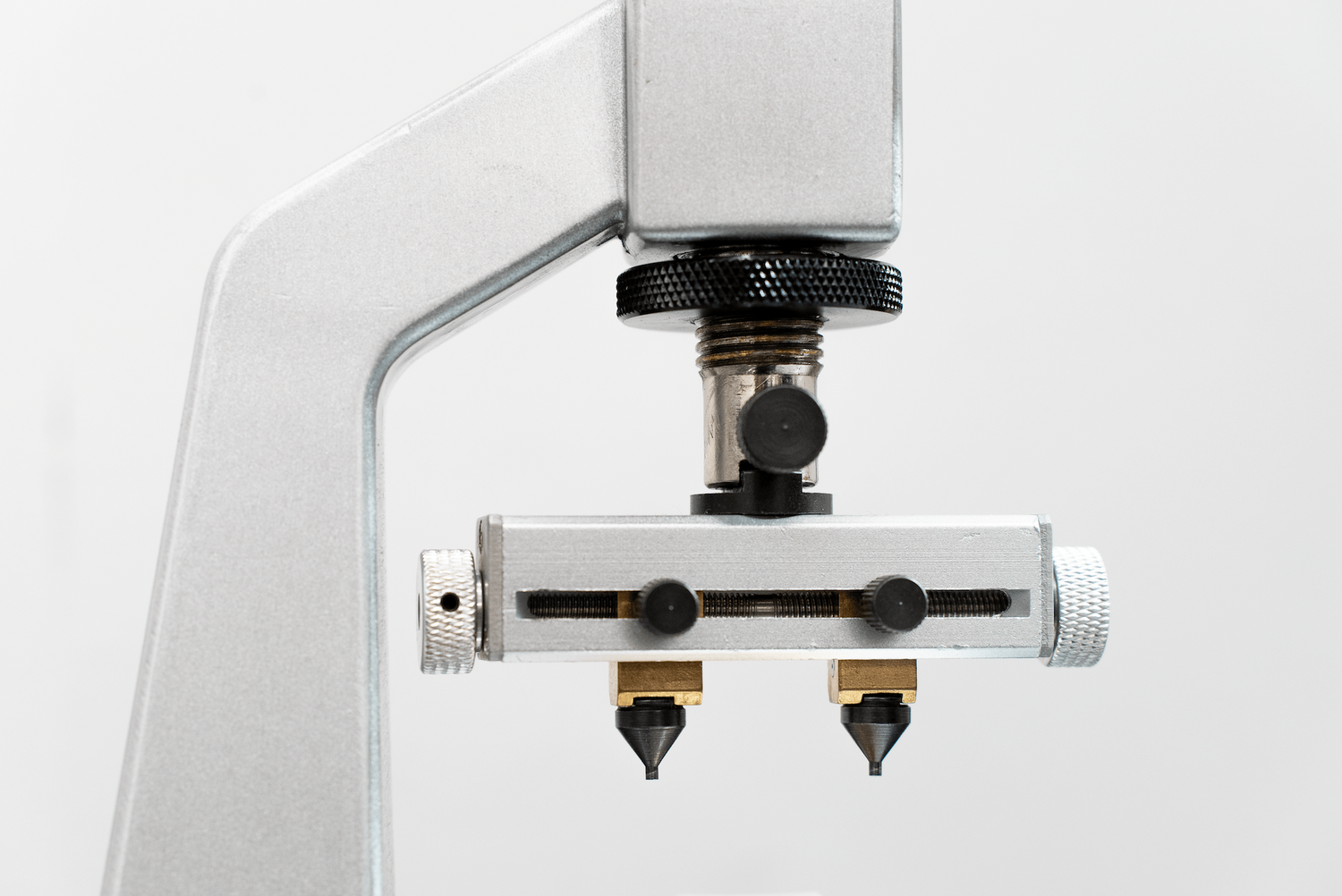

THE FOB PARIS WORKSHOP

Design place where watchmakers and designers come together. Within the workshop, creators experiment and develop new techniques. Modeling, prototyping, surface treatment, finishing and assembly. Processes carried out between Besançon and the Marais district, in the center of Paris.

THE CHOICE OF COMPONENTS

Skeleton automatic movements, made in Switzerland and Japan, adjusted in Paris. Carefully selected components. Scratch and impact resistant sapphire crystals, anti-reflective treatments, 316L stainless steel and high quality PVD coloring.

FOB watches combine aesthetics, reliability and durability.

THE TIME CAPSULES PROJECT

Playing with the infinite potential of watchmaking creation also means creating extraordinary pieces. Under the ‘TIME CAPSULES’ collection, FOB imagines new collaborations.

Made with designers, artists and jewelers who share their creativity with French watchmaking.